Ultrasonic meters vs. Electromagnetic meters

Selecting the right flow meter technology for your system is critical. However, as every meter technology has both advantages and disadvantages – some of which are explored in the following – your ability to rely on the meter’s readings will very much depend on the application

What is ultrasonic metering technology?

Ultrasonic meters measure the flow rates without using moving parts. Ultrasonic meters come in two variants:

Transit time flow meters measure the time it takes for an ultrasonic signal to pass from one transmitter to another. In other words, a meter has two transmitters that each emit a signal. If there is no water passing through the meter, the two signal speeds will be identical. When water passes through the meter the signal that travels with the flow of the water will be faster than the other signal as it travels against the stream. This way, the meter can, very accurately, measure the exact amount of water that passes through it. You can see a more detailed explanation of that by clicking here.

Doppler flow meters depend on suspended bubbles and particles in the water to reflect the ultrasonic signal because this provides a shift in the frequency. The way this works is that shifts in frequency are directly linked to the velocity of the water. We don't use the Doppler flow metering principle in our meters, so we won't educate you further in that. If you want to learn more about the Doppler principle you can read this more in-depth article about Doppler flow meters.

What is electromagnetic metering technology?

In an electromagnetic (mag) meter, a magnetic field is applied at a 90° to the direction of the water flow. When water passes through the field, the meter generates a voltage that matches the velocity of the water. As the meter’s in-side diameter is known, the flow rate can then be calculated. This technology requires that the water measured is conductive otherwise the meter won't be able to correctly calculate the flow-rate.

Both ultrasonic meters and mag meters are static meters. A static meter has some advantages which set them apart from regular mechanical meters. Check out the photo below to get a quick overview of the most common differences between mechanical and static meters.

Operations

Chalk and other particles

Static meters have no moving parts that can be affected by chalk and other particles. However, there is a risk of calcareous deposits that can change the size of the meter’s inner diameter and change the velocity of the water passing the meter. Over time, this will decrease accuracy. Also, mag meters are fairly sensitive to mineral deposits on the pick-up electrodes as the minerals can cause local potential differences resulting in an apparent flow rate that does not reflect the actual flow velocity. The characteristic of the water determines how big a risk this is. More and more meters are made of a composite material that minimizes deposits in the meter considerably because of its smooth surface.

Noise

Acoustic noise is sometimes incorrectly referred to as a challenge for ultrasonic meters. Ultrasonic meters use the frequency of 1 MHz, which is not even close to the frequency for acoustic noise. When mag meters measure very small flows it is done on the basis of very little voltage. When you measure very little voltage, you will be more vulnerable to electric noise. The design of the mag meter must, therefore, take this into account. For bigger flows, you have higher voltage which reduces the risk of being affected by electric noise. As mag meters use magnetism to perform the measurement it can, by its very nature, be affected by magnetism, which necessitates an alarm for magnetic tampering.

False readings

In general, the lower the start flow you choose for your meter, the higher the risk you face of the meter counting when no average flow is present. This applies to both mag and ultrasonic meters. It depends on how you handle the data i.e. which flows you measure. Kamstrup meters have a start flow down to 2 liters/h, which does not cause any problems. Meters with a lower start flow have a higher risk of catching zero flow measurements due to noise or maybe by boosting the negative flow they have when changing the magnetic field in the meter. Residential mag meters have been known to count before installation has been completed as a result of picking up electronic noise. The same thing can happen if the meter experiences pulsed flow synchronized with the sampling. For this reason, a cut-off flow is usually introduced, below which the flow measurement is truncated. The challenge when manufacturing quality flow meters is to continuously improve the signal-to-noise ratio thereby lowering the cut off flow rate.

Accuracy

Sampling rate

Both ultrasonic and mag meters are capable of very high accuracy. One of the factors that determine the level of accuracy is the sample rate, which all smart meters use. The measurement is a snapshot of the current flow. Like any type of digital sampling, this will integrate the measurements over time, leading to the calculation of the final volume. What you wish to achieve is an error curve as close to reality as possible in the measuring points that are important to you. Combined with Kamstrup’s comprehension of the handling of data, this sampling rate makes Kamstrup meters the most accurate on the market.

Flow corrections

The large dynamic range combined with the nature of the meter technology causes both ultrasonic and mag meters to be sensitive to variations in the fluid low-velocity profile across the pipe. As a result, these types of meters are somewhat nonlinear, especially at low flow rates, which necessitates the use of flow corrections. For small dimensions, ultrasonic meters only measure the middle part of the flow, which is where the velocity is the highest. It is, therefore, necessary to correct for the part of the flow that is not covered. For larger dimensions, more reflectors are used to cover all of the flow. Regardless of the dimension, mag meters need a compatible magnetic field. This is only possible in theory, and therefore a correction is required because of the non-compatible magnetic field.

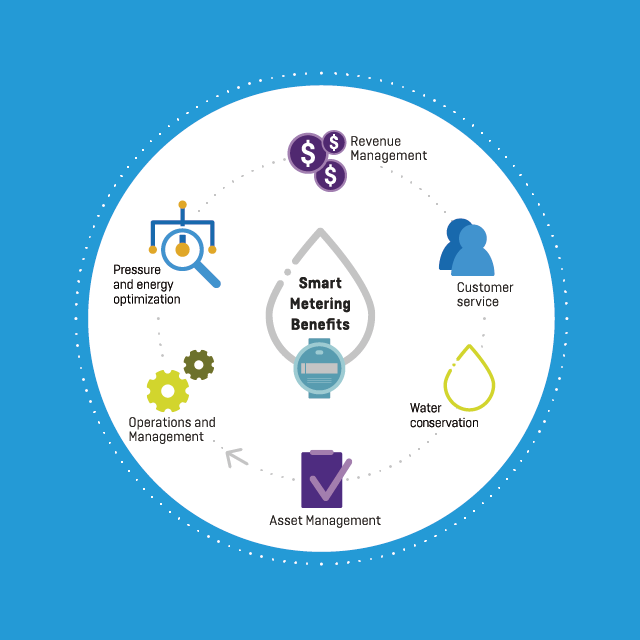

Do you want to say goodbye to your traditional water meter?

Learn more about our ultrasonic principle or read more about our smart metering solutions.

Author

September 4, 2019