Posted on Monday, November 19, 2018 by Steen Schelle Jensen

Three real-life examples of data-driven distribution optimisation

See how utilites use Heat Intelligence to tackle common challenges and optimise their distribution

Digital technologies hold the potential to make the entire energy system more efficient, reliable and intelligent. For district heating utilities, one of the areas that hold the most potential is distribution. Characterised by being closely linked to consumer behavior and energy performance of buildings, this area represents enormous operational costs and long-term investments – but it requires the right tool for the job.

Kamstrup’s new analytics tool, Heat Intelligence, combines heat meter data with a digital GIS model of the pipe network to provide the basis for a data-driven model of how temperatures and flow spread throughout the distribution network.

The following three examples from collaborations with our customers show how utilities can utilise this new level of transparency to tackle three common challenges and optimise their distribution.

Example 1: Localisation of leakages

Leakages in the distribution network cause heat loss and may over time damage its pipes. Heat Intelligence makes it possible for you to pinpoint leakages by identifying temperature outliers in the model data set.

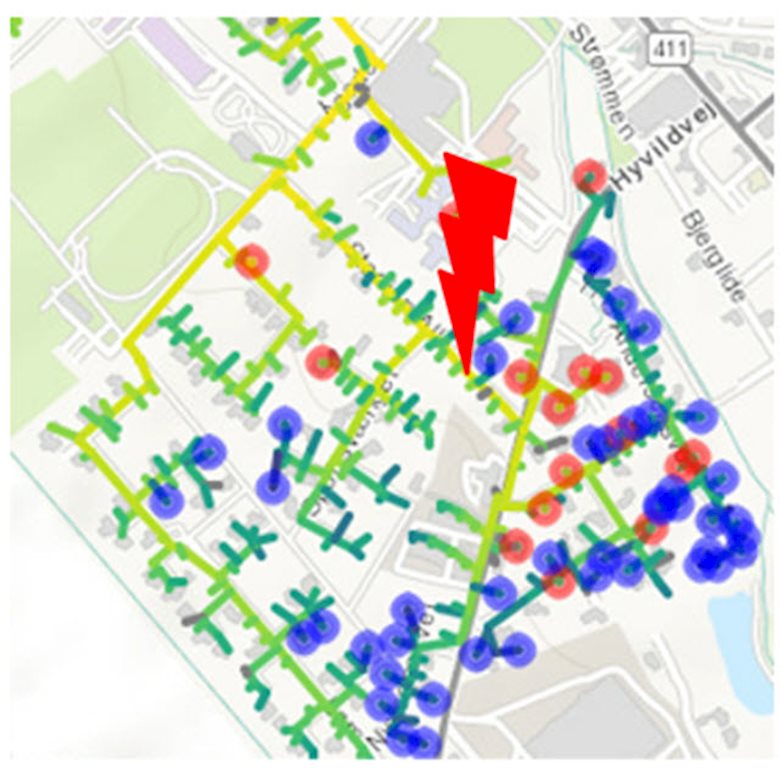

In Figure 1, Heat Intelligence has detected multiple temperature outliers (red and blue dots), where the temperatures measured by the meters deviate significantly from the predicted temperature values. A big leak will influence all meter measurements at positions downstream from that leak. In this way, the leak can be located near the point indicated in the figure.

Leakages in the distribution network cause heat loss and may over time damage its pipes. Heat Intelligence makes it possible for you to pinpoint leakages by identifying temperature outliers in the model data set.

In Figure 1, Heat Intelligence has detected multiple temperature outliers (red and blue dots), where the temperatures measured by the meters deviate significantly from the predicted temperature values. A big leak will influence all meter measurements at positions downstream from that leak. In this way, the leak can be located near the point indicated in the figure.

Example 2: Identification of bypasses

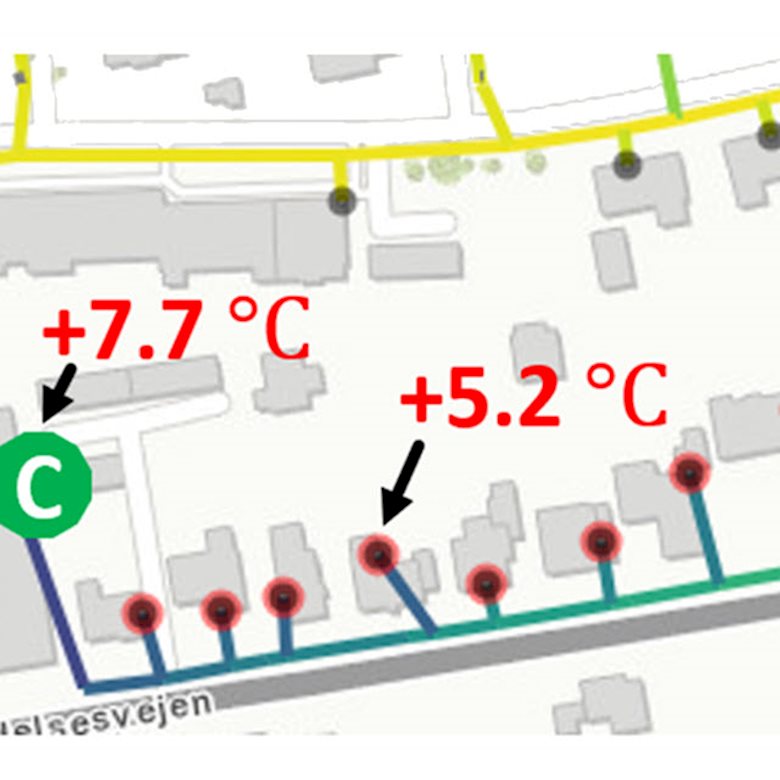

eat Intelligence allows you to detect losses due to bypasses in the distribution network. In Figure 2, the red dots indicate where the measured temperature deviates from the expected temperature according to the predictions from Heat Intelligence. These deviations increase along the downstream direction.

Consequently, it can be inferred that a circulation (C) is placed close to the last consumer on a branch pipe. With an estimate of the amount of flow caused by the circulation, you will subsequently be able to regulate and evaluate the efficiency of the circulation.

Example 3: Detection of stationary flow

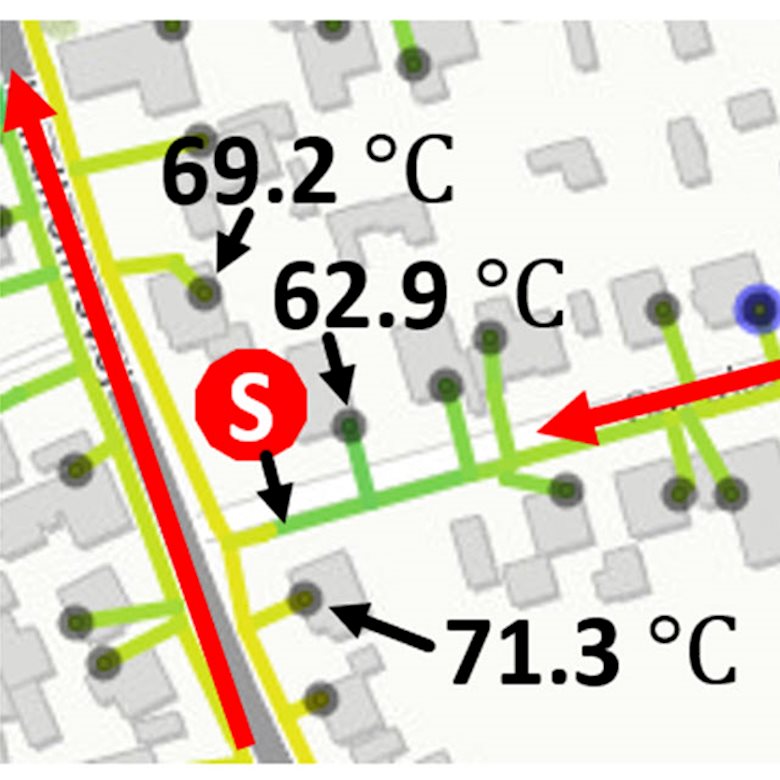

Rings in the network can cause stationary flow, which may result in problems with very low supply temperatures that negatively affect your quality of delivery. With Heat Intelligence, you can identify regions in the distribution network with a high risk of stationary flow. It uses meter measurements to probe the in and out coming flow in the network rings, as well as the temperatures around them.

Rings in the network can cause stationary flow, which may result in problems with very low supply temperatures that negatively affect your quality of delivery. With Heat Intelligence, you can identify regions in the distribution network with a high risk of stationary flow. It uses meter measurements to probe the in and out coming flow in the network rings, as well as the temperatures around them.

How do you optimise your distribution network?

Do you want to learn more about data analytics for your utility?

Learn more about our analytics tool, Heat Intelligence, right here.