Posted on Friday, January 4, 2019 by Morten Karstoft Rasmussen

Data located significant heat loss in the service pipes!

How a local district heating utility used data from intelligent meters to reduce heat loss and increase forward temperatures

Intelligent meters in the network deliver actionable insights

Heat

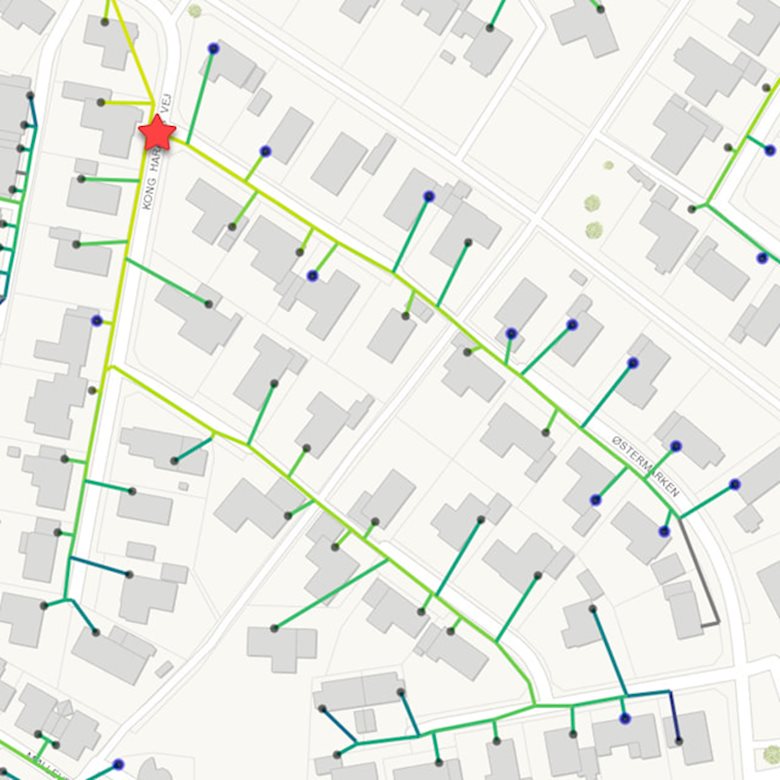

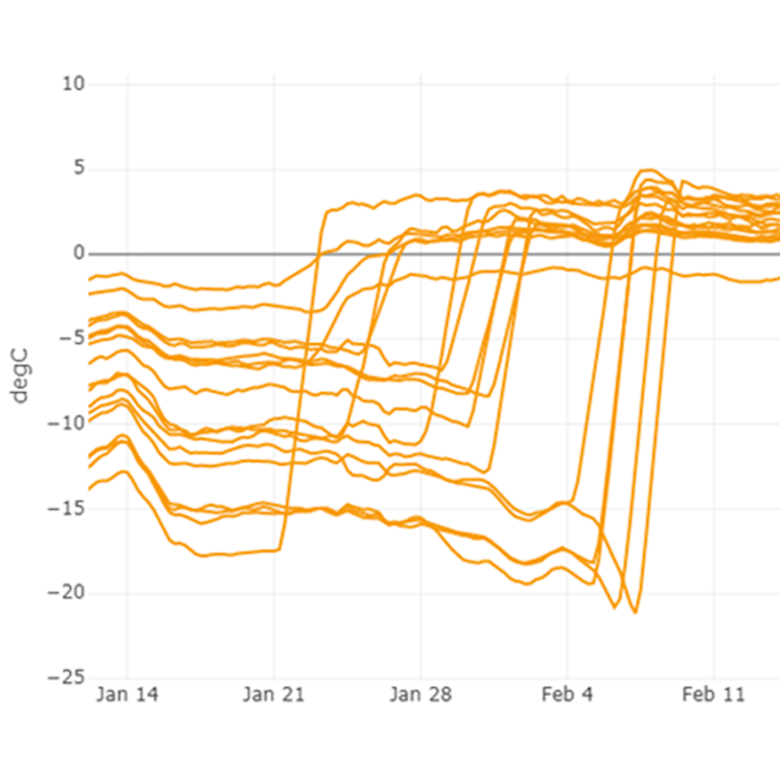

Intelligence calculates the expected temperature for all consumers, given the

estimated temperature in the branch pipe. The difference from the expected temperatures for all

consumers downstream relative to the point marked with the red star in Figure 1

are plotted in Figure 2. The chart shows that for all consumers a lower

temperature than expected was measured; however, after renovating the pipes all temperatures “jumped” up close to zero (which is the expected value).

It is even possible to tell on which day the service connections were renewed over the

approximately two weeks period of renovation works.

Reduced heat loss

Where to renovate next?

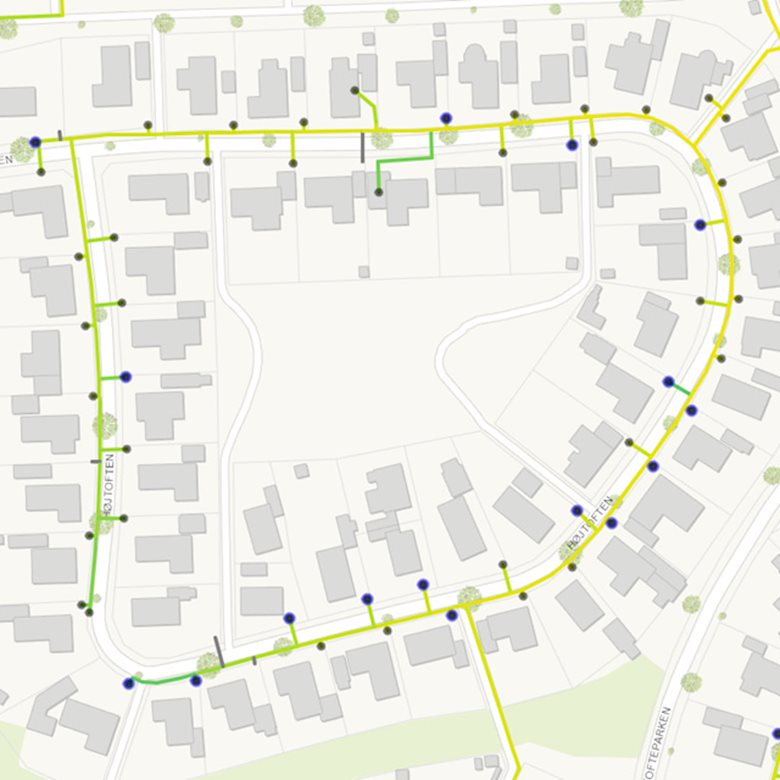

Figure 3 shows another area of the network where Heat Intelligence has detected service pipes with high heat loss (marked with blue circles). In the same way as above, the estimated temperature deviations can also here be used to calculate the attainable reduction in heat loss.

The temperature deviations identified by Heat Intelligence for the consumers marked with blue dots in Figure 3 are in the same order of magnitude as above, i.e. approximately 10 °C below the expected value. Consequently, it is also possible to obtain a reduction in heat loss by approximately 7.8 MWh per consumer per year in this region of the network. These findings should, of course, be taken into consideration when the utility plans for the next renovation.

How does Heat Intelligence work?

Do you want to locate heat loss in your utility?

Learn more about our analytics tool, Heat Intelligence, right here.

_____________________

*In the present case, estimates are used based on average values from the 17 consumers in Figure 1. Heat Intelligence estimates the forward temperatures in the main pipe supplying the service connections for each consumer. Using these estimates, together with meter data, heat loss coefficients can be estimated before and after the renovation. It is estimated that, by renewing the service connections, the heat loss coefficient is improved with a factor 6.5. This translates to a difference in heat loss of approximately 1.1 W/m/K. Using approximate values for the service connection lengths, the supply and ambient temperatures as well as the consumption, this difference corresponds to a heat loss per consumer per year of approximately 7.8 MWh. This is a rough estimation - a more precise estimation of the heat loss per consumer per year requires a more careful analysis using data from each individual consumer and service connection.